TAIHANG STEEL (QINGDAO)CO., LTD.

Focus on the steel industry for more than 20 years.

Since 2019, the company has expanded its services to the world. It has been involved in the steel industry for nearly 20 years and has accumulated rich industry knowledge and experience. Whether it is carbon steel, stainless steel, galvanized, color-coated or profiles, we have in-depth research and rich practical experience. Each product embodies our efforts and wisdom to ensure that we provide customers with the highest quality and most reliable steel products. Whether it is construction, transportation, energy or manufacturing, we have a complete product line to meet your needs. Committed to innovation and excellence, we continue to provide first-class customized steel and metal solutions to customers around the world.

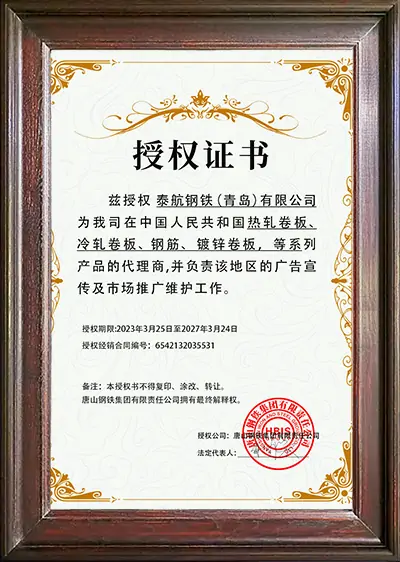

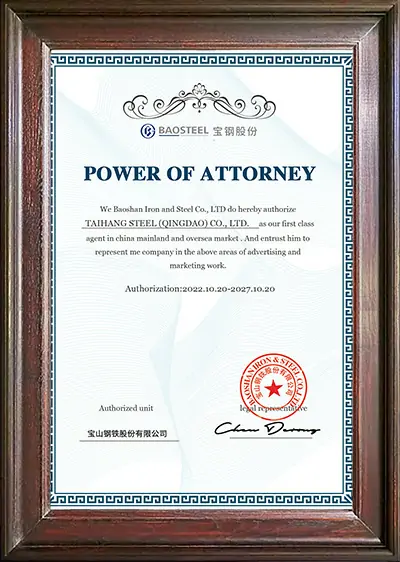

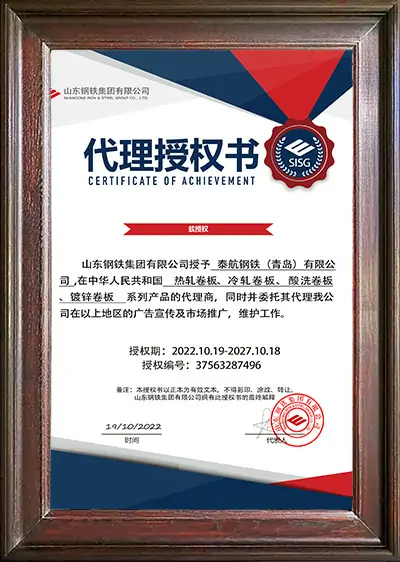

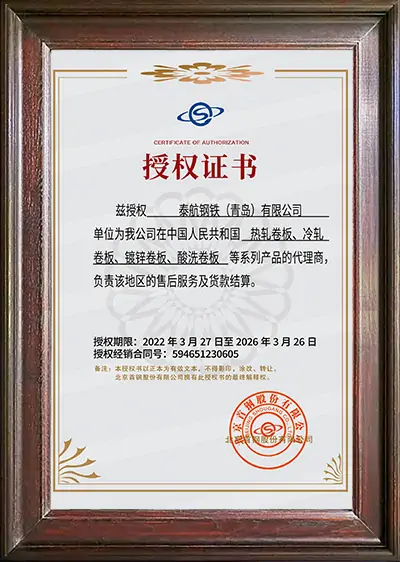

Integrity is the foundation of our business. We uphold the principles of openness, fairness and justice, and have established stable and lasting cooperative relations with domestic and foreign steel mills. We strictly control product quality to ensure that every ton of steel meets national standards and provide customers with high-quality products. At the same time, we pay attention to after-sales service, always provide customers with thoughtful service, and win the trust and praise of our customers. We serve global customers with a global vision. No matter where you are, we try our best to provide you with high-quality steel products and professional solutions.

In the future, we will continue to uphold the concepts of integrity, quality, high-end, green and ecological, provide better products and services to global customers, and contribute to the long-term stable development and progress of the steel industry.

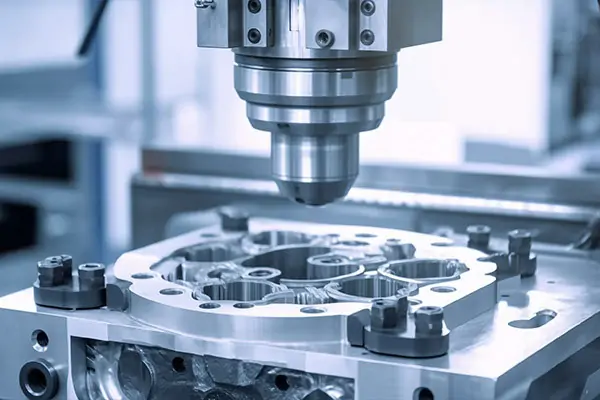

STEEL PROCESSING TECHNOLOGY

Steel is a commonly used metal material, widely used in construction, machinery, automobiles, electronics, aviation and other fields. In order to meet different needs, steel can be processed through various processes to change its shape, size and performance.

APPLICATION AREAS