AISI/SAE 4140 Carbon Steel Bar

4140 is a 1% chromium-molybdenum medium hardenability general-purpose high-strength steel, usually hardened and tempered in the tensile range of 850-1000 Mpa (condition T). 4140 now have improved machinability, which greatly increases feed and/or speed, while extending tool life without affecting mechanical properties. The prehardening and tempering 4140 can be further case hardened by flame or induction hardening and nitriding.

Categories:

Keywords:

AISI/SAE 4140 Carbon Steel Bar

PRODUCT DETAILS

AISI/SAE 4140 Carbon Steel Bar Description

4140 is a 1% chromium-molybdenum medium hardenability general-purpose high-strength steel, usually hardened and tempered in the tensile range of 850-1000 Mpa (condition T). 4140 now have improved machinability, which greatly increases feed and/or speed, while extending tool life without affecting mechanical properties. The prehardening and tempering 4140 can be further case hardened by flame or induction hardening and nitriding.

Product Parameters

Product Name | AISI/SAE 4140 Carbon Steel Bar | |||

Standard | EN/DIN/JIS/ASTM/BS/ASME/AISI, etc. | |||

Common Round Bar Specifications | 3.0-50.8 mm, Over 50.8-300mm | |||

Flat Steel Common Specifications | 6.35x12.7mm, 6.35x25.4mm, 12.7x25.4mm | |||

Hexagon Bar Common Specifications | AF5.8mm-17mm | |||

Square Bar Common Specifications | AF2mm-14mm, AF6.35mm, 9.5mm, 12.7mm, 15.98mm, 19.0mm, 25.4mm | |||

Length | 1-6meters, Size Accept Custom | |||

Diameter(mm) | Hot Rolling Round Bar | 25-600 | Cold Rolling Square Bar | 6-50.8 |

Hot Rolling Square Bar | 21-54 | Cold Rolling Hexagon Bar | 9.5-65 | |

Cold Rolling Round bar | 6-101.6 | Forged Rebar | 200-1000 | |

Surface Process | Bright, Polished, Black | |||

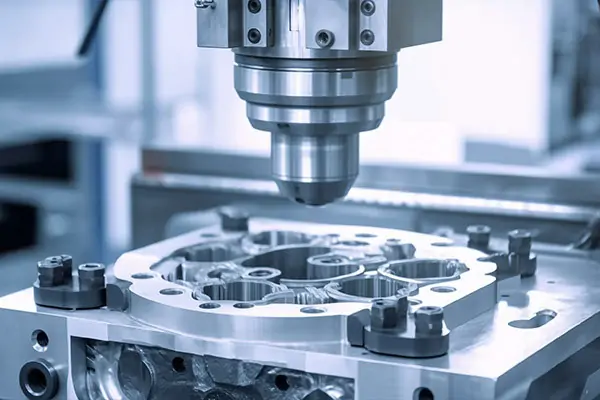

Other Services | Machining(cnc), Centerless Grinding(cg), Heat Treatment, Annealing, Pickling, Polishing, Rolling, Forging, Cutting, Bending, Small Machining, etc. | |||

Chemical Composition

Grade | Mn | S | C | P | Si | Cr | Ni |

AISI 4140 | 0.75-1.00 | 0.035 | 0.38-0.43 | 0.035 | 0.20-0.35 | 0.8-1.1 | 0.15-0.25 |

Mechanical Properties

Grade | Tensile Strength psi | Yield Strength psi | Elongation % | Hardness HRC |

AISI 4140 | 100k | 80k | 20 | 18-22 |

Scope of Application

SAE 4140 are widely used in most industrial sectors, with a wide range of applications, such as: adapters, spindles, axles, bolts, crankshafts, connecting rods, chuck bodies, chucks, conveyor belt pins and rollers, ejection pins, forks, gears, Guide rods, hydraulic shafts and parts, lathe spindles, logging parts, milling spindles, motor shafts, nuts, clamping rods, various pins, pins, pump shafts, plungers, sleeve, spindle, sprocket, stud bolt, tool holder, torsion bar, worm, etc.

| USA | Japan | Germany | U.K. |

| France | Italy | Spain | Switzerland | China | |

AISI/SAE | JIS | W‐nr. | DIN | BS | EN | AFNOR | UNI | UNE | SS | GB |

A570.36 | STKM 12A | 1.0038 | RSt.37‐2 | 4360 | ‐ | E 24‐2 | ‐ | ‐ | 1311 | 15 |

- | STKM 12C | - | - | 40 C | - | Ne | - | - | - | - |

1015 | ‐ | 1.0401 | C15 | 080M15 | ‐ | CC12 | C15, C16 | F.111 | 1350 | 15 |

1020 | ‐ | 1.0402 | C22 | 050A20 | 2C | CC20 | C20, C21 | F.112 | 1450 | 20 |

1213 | SUM22 | 1.0715 | 9SMn28 | 230M07 | 1A | S250 | CF9SMn28 | F.2111 | 1912 | Y15 |

11SMn28 | ||||||||||

12L13 | SUM22L | 1.0718 | 9SMnPb28 | ‐ | ‐ | S250Pb | CF9SMnPb28 | 11SMnPb28 | 1914 | ‐ |

‐ | ‐ | 1.0722 | 10SPb20 | ‐ | ‐ | 10PbF2 | CF10Pb20 | 10SPb20 | ‐ | ‐ |

1215 | ‐ | 1.0736 | 9SMn36 | 240M07 | 1B | S300 | CF9SMn36 | 12SMn35 | ‐ | Y13 |

12L14 | ‐ | 1.0737 | 9SMnPb36 | ‐ | ‐ | S300PB | CF9SMnPb36 | 12SMnP35 | 1926 | ‐ |

1015 | S15C | 1.1141 | Ck15 | 080M15 | 32C | XC12 | C16 | C15K | 1370 | 15 |

1025 | S25C | 1.1158 | Ck25 | ‐ | ‐ | ‐ | ‐ | ‐ | ‐ | 25 |

A572-60 | ‐ | 1.890 | StE380 | 4360 55 | ‐ | ‐ | FeE390KG | ‐ | 2145 | ‐ |

1035 | ‐ | 1.0501 | C35 | 060A35 | ‐ | CC35 | C35 | F.113 | 1550 | 35 |

1045 | ‐ | 1.0503 | C45 | 080M46 | ‐ | CC45 | C45 | F.114 | 1650 | 45 |

1140 | ‐ | 1.0726 | 35S20 | 212M36 | 8M | 35MF4 | ‐ | F210G | 1957 | ‐ |

1039 | ‐ | 1.1157 | 40Mn4 | 150M36 | 15 | 35M5 | ‐ | ‐ | ‐ | 40Mn |

1335 | SMn438(H) | 1.1167 | 36Mn5 | ‐ | ‐ | 40M5 | ‐ | 36Mn5 | 2120 | 35Mn2 |

1330 | SCMn1 | 1.1170 | 28Mn6 | 150M28 | 14A | 20M5 | C28Mn | ‐ | ‐ | 30Mn |

1035 | S35C | 1.1183 | Cf35 | 060A35 | ‐ | XC38TS | C36 | ‐ | 1572 | 35Mn |

1045 | S45C | 1.1191 | Ck45 | 080M46 | ‐ | XC42 | C45 | C45K | 1672 | Ck45 |

1050 | S50C | 1.1213 | Cf53 | 060A52 | ‐ | XC48TS | C53 | ‐ | 1674 | 50 |

1055 | ‐ | 1.0535 | C55 | 070M55 | 9 | ‐ | C55 | ‐ | 1655 | 55 |

1060 | ‐ | 1.0601 | C60 | 080A62 | 43D | CC55 | C60 | ‐ | ‐ | 60 |

1055 | S55C | 1.1203 | Ck55 | 070M55 | ‐ | XC55 | C50 | C55K | ‐ | 55 |

1060 | S58C | 1.1221 | Ck60 | 080A62 | 43D | XC60 | C60 | ‐ | 1678 | 60Mn |

1095 | ‐ | 1.1274 | Ck101 | 060A96 | ‐ | XC100 | ‐ | F.5117 | 1870 | ‐ |

W1 | SK3 | 1.1545 | C105W1 | BW1A | ‐ | Y105 | C36KU | F.5118 | 1880 | ‐ |

W210 | SUP4 | 1.1545 | C105W1 | BW2 | ‐ | Y120 | C120KU | F.515 | 2900 | ‐ |

FACTORY APPEARANCE

Whether it is carbon steel, stainless steel, galvanized, color-coated or profiles, we have in-depth research and rich practical experience. Each product embodies our efforts and wisdom to ensure that we provide customers with the highest quality and most reliable steel products.

PACKING AND DELIVERY

We can provide,

wooden pallet packaging,

Wooden packing,

Steel strapping packaging,

Plastic packaging and other packaging methods.

We are willing to package and ship products according to the weight, specifications, materials, economic costs and customer requirements.

We can provide container or bulk transportation, road, rail or inland waterway and other land transportation methods for export. Of course, if there are special requirements, we can also use air transportation

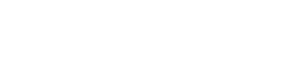

CUSTOMER FEEDBACK

We strictly control product quality to ensure that every ton of steel meets national standards and provide customers with high-quality products. At the same time, we pay attention to after-sales service and always provide customers with thoughtful services, which has won the trust and praise of customers. We serve global customers with a global vision.

WHY CHOOSE TAIHANG STEEL

For the steel industry, customers value quality and after-sales service the most. We always adhere to high standards and strict requirements and are committed to becoming your preferred partner.

Quality Assurance

We are well aware that quality is the lifeline of the steel industry. Therefore, we adhere to strict quality control processes to ensure that each batch of steel products meets national standards and provides solid protection for your projects.

Industry Experience

With many years of industry experience, we have a deep understanding of market demand and can provide customized products and services according to customer needs to ensure that your business is fully supported.

Professional Team

We have a professional team with rich technical knowledge and practical experience. No matter what problems we encounter, we can respond quickly and provide effective solutions.

After-sales Service

We value the feedback of every customer and provide a full range of after-sales services to ensure that you have no worries during the cooperation process.

PRODUCT MEASUREMENTS

GET A FREE QUOTE

If you have any needs, we can tailor professional steel solutions for you.

APPLICATION AREAS

Automotive

Shipbuilding

Building Manufacturing

Machine Manufacturing

FAQ

Q:Once the products received by customer were found not comply with the products or contract demands, what will you do?

Q:How about the payment terms?

Q:Whether to accept inspection company and factory?

Q:How to ensure that the quantity and material delivered meet customer requirements?

Q:What is the delivery time?

Q:What is your MOQ?

RELATED PRODUCTS

GET A FREE QUOTE

For the steel industry, customers value quality and after-sales service the most. We always adhere to high standards and strict requirements and are committed to becoming your preferred partner.